We have to better position our solutions in the widening shop window.

We have to better position our solutions in the widening shop window.

We’re working hard as a sector to raise our profile, as this year’s Global Lifting Awareness Day (GLAD; see insert) will prove on 18 July, but we don’t always do enough to help those who find us understand what our products do, and, more importantly, how they help.

Many people flicking through the pages of this journal will be familiar with all types of cranes, hoists, hooks, shackles, and slings; but others, especially those new to end user communities, are looking to all of our content for help in learning more about our wares. Imagine being a new starter at a wastewater plant or heating, ventilation, air-conditioning, and refrigeration (HVACR) company. Countless scenarios where an item needs safe lifting and moving will be presented every shift, and experienced operatives aren’t always good at passing on knowledge.

Our hard work will go to waste if, when we shine a spotlight on our industry, people remain in the dark. We want to celebrate lifting as a specialist market that delivers life-changing, life-saving solutions to the point of use, but complicating our messaging, or focusing on the wrong elements of our equipment and technologies, creates confusion.

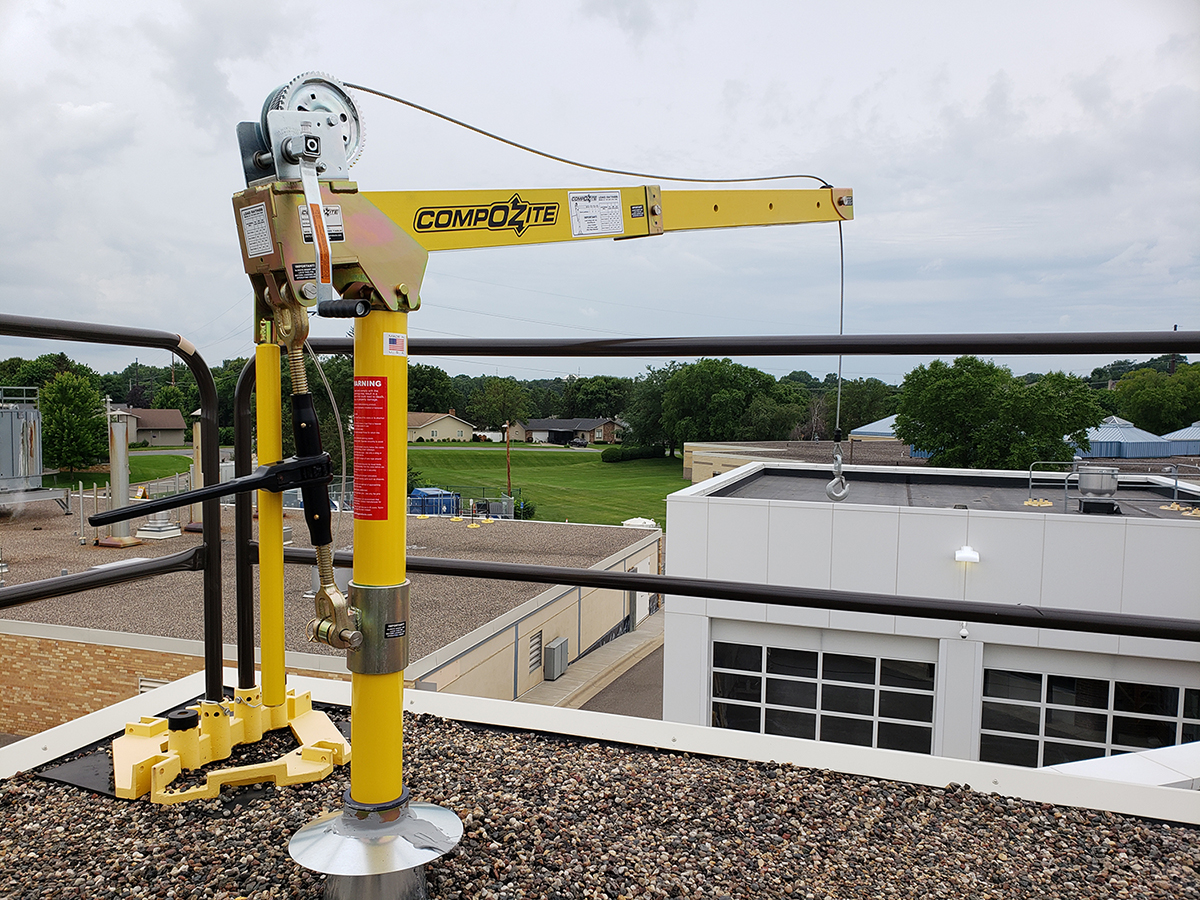

To explain my point, I want to take an opportunity to chart the journey of the once humble davit crane (sometimes called a davit, davit arm, or, mistakenly, a jib crane). The intention is not to promote our company commercially, but to demonstrate how lifting tools, like this, can help to change — and lift — the world, if we present them properly.

The first thing we can do as a manufacturer or provider of equipment is to get good at answering simple questions:

• What does your company do?

• What does this crane do?

• Why should I use it instead of that one over there?

• How much can it lift?

• How do I assemble it?

• And so on

They sound straightforward to answer but have a listen to conversations next time you’re in an elevator, sitting next to a group at a breakfast meeting, or even at a trade show; it’s amazing how poorly simple questions are answered.

Here’s a question that everyone at our company has got good at handling:

What is a davit crane?

The answer: a davit crane is made up of a mast, boom, and winch.

People instantly picture it, even if we’re not in an environment at the time where we can immediately produce an image.

We add: a base and cable assembly are needed to operate a davit crane.

It’s almost as if the eyes of the person asking the questions light up; they start to understand and they become intrigued.

What’s a davit crane base?

We get asked a lot of questions about davit crane bases, and being good at answering them has certainly helped. We once sold four composite davit cranes and 80 bases to a single wastewater facility, for example.

As discussed in the main body of this article, a davit crane is made up of a mast, boom, and winch, but a base and cable assembly are needed to operate it. Even throughout a single facility, there might be a need for permanent, static, or frequently moved davit cranes. Regardless, it is necessary to choose an appropriate base; there are three main options (each one comes with a mounting template), plus our new wheel base:

Pedestal: commonly bolted to the floor in a facility. Users mount the base where they need to make a lift and move the crane from base to base.

Socket: used in an area where the installer will pour cement around the base to keep the surface area flat and create high mounting strength.

Wall-mount: allows a davit crane to be attached to the wall of a facility to save floorspace, perhaps on a production line or at a workstation.

Wheel: allows users to move the crane to various points within a facility; the applications are limitless. The main benefit is that users do not have to permanently mount a base at the pick location.

Of course, it might also be the case that we’ve explained the product so well that a mast, boom, winch, base, and cable assembly, are not the right choice. We can then move the conversation onto other equipment or help them find what they’re looking for. We are a material handling company that offers unique lifting solutions, of which davits are a big part of that product mix, but we don’t have a solution for every end-use scenario — nobody does, and they shouldn’t pretend to.

This is important because the way we interact with newcomers to our equipment ranges creates a first impression of our wider sector. I said at the outset that we need to think about how we position our products in a shop window, and we’re all shopkeepers working in the larger lifting equipment superstore. The way we listen, respond, consult, help, guide, and support will all dictate how we’re perceived as an industry. A retail worker knows that if they understand what they’re selling and they’re polite to the customer, they’re more likely to put something in a bag for them to take home.

There are many different products that can be categorised as lifting equipment. Add in all the ancillary tools and supporting technologies, and the list gets longer still. If explaining what a product is, what it does, and how it does it, are all important, being able to point out how it is similar and different to another solution is also necessary.

Again, we can use the davit crane as a case in point. We often get asked how a davit is different from a jib crane. Remembering what a davit crane is (made up of a mast, boom, and winch), a jib crane is made up of a mast and an I-beam. This allows a trolley mounted to the I-beam to accept a chain hoist, allowing the load to wheel back and forth on the beam. There are similarities, but important differences.

As salespeople, what we need to focus on is what a product does, always steering the conversation towards the right one being selected for the job or application at hand. Portable davit cranes are more cost effective and versatile than jibs and are more popular with those sourcing lifting equipment for environments where there might be many requirements for the same crane on a single day, all in different locations, at the same facility.

This type of dialogue has been happening in my life ever since I saw my first davit crane back in 1988, when I was immediately drawn to the mechanics of the mast, boom, winch, base, and cable assembly; it was a product that made sense to me, and I saw its potential. Fast forward nearly four decades and we’re at the point in davit manufacturing where we’ve seen composite materials used to add corrosion resistance and reduce the weight of cranes by 40% compared to traditional steel models.

Have your answers ready

Global Lifting Awareness Day, which will be celebrated at the hashtag, #GLAD2024, on 18 July, will invite newcomers to the industry to explore our product ranges and ask us questions about them. Are you ready?

It was great to see the Lifting Equipment Engineers Association (LEEA) moving products, inspection, and training to the front of its campaign, sharpening its focus on the importance of surrounding these three cornerstones of lifting with high quality.

As LEEA says, we want people to make buying choices always based on quality. To make that happen, we have to present ourselves as experts in our field and authentic stakeholders that have end users’ best interests at heart.

Someone might buy their first davit crane as a result of #GLAD2024, which is a prospect I find as exciting as seeing my first davit system 36 years ago.

By getting good at answering simple questions, and authentically positioning davit cranes only as the solution in the right instances, we’ve taken them on a journey from zero to hero. It didn’t happen overnight; we were the first company to try it and the material took time to be accepted in the marketplace. It was a real paradigm shift for those that were used to davits made from steel. To a lesser extent, we also had to walk the market to acceptance of our Tele-Pro model, which allows users to leverage the benefits of other lifting technologies in the range, while telescoping the boom in and out under load. We now have six different lines of davits made from carbon steel, aluminium, pultruded fibreglass, and carbon fibre.

What helped us take all these innovative steps was that we had a reputation for presenting our products in a way that was understood and trusted. Were it not built on those foundations, I’m not sure we could have taken this journey, and davit cranes wouldn’t be used to the extent to which they are from automative to warehouse facilities, and everywhere in between. Our composite and telescope series are now our most popular davits. There’s certainly a lesson there that the lifting industry — indeed, any sector — can learn from.

That said, our work continues. One has never stopped perfecting the art of presenting industrial products to market. We’re getting more and more eyeballs on our sector. These newcomers will be curious and inquisitive, and we must make sure we have the answers to, one, keep them interested; and two, leverage their involvement so our products reach their full, innovative potential.

Steve Napieralski has been in the lifting and rigging industry for 36 years — seven years working for a manufacturer of lifting equipment before setting up his own businesses. In 1995, he started as a manufacturer’s representative dedicated to the lifting and rigging industry, and in 2004 he founded OZ Lifting Products. He is a graduate of Winona State University and holds three patents. Napieralski has been affiliated with associations since 1992 with his membership in Associated Wire Rope Fabricators (AWRF).